Seal Test / Sealing Test department Store|food seal strength testing : trade Six new reasons drive home the importance of determining seal integrity using these common food packaging test methods. web19 de abr. de 2013 · Confira, no tutorial abaixo, como atualizar o navegador da Microsoft .

{plog:ftitle_list}

WEBclassificação. Oferta Especial: R$1,90 no 1º mês. Assine a Folha. Campeonato Brasileiro 2021 - Série A - Classificação. + campeonatos. Classificados para a Libertadores Zona .

Testing the integrity of package seals helps ensure that food packaging provides required product protection. Sustainable packaging alternatives, lower cost packaging, and variations in production line sealing parameters are frequently . Six new reasons drive home the importance of determining seal integrity using these common food packaging test methods. The article describes and compares various test methods that can be used including the gas leak test, ultrasonic seal test, vacuum decay test, bubble emission test, dye .By prioritizing seal integrity testing, you’re taking a crucial step toward upholding excellence in your food packaging processes. FlexPak Leak Detectors provide the reliable, industry-leading testing solutions you need to maintain the highest .

Seal strength test methods evaluate the integrity of seals on various types of packaging, from food containers to medical supplies. These tests measure the force required to separate .Seal tests ISO11607-2 (Validation requirements for forming, sealing and assembly processes), requires Operational Qualification (OQ) of packaging devices to be carried out and documented. The OQ is requiring providing proof of: Intact seal for a specific seal width No channels or open seals No punctures or tears in seals No material delaminating or separation The OQ needs toMaterials Lot 2 with all seals passing gross leak and fine leak test mean of 4.5E-10 atm-cm3/sec air with Std Dev 0.35. The Sealing Schedule 3 shows that a sealing technique has enough margin to get near identical results even with slight differences in materials resulting from different lots from material suppliers. Dye penetration test: An operator applies a dye to one side of the seal area and then examines the other side of the seal to assess if the dye transferred through the seal. Detectable leaks are six orders of magnitude .

+1 to using spinfits on the noble line. I have been playing around with tips for my noble 4 and my favorite pair is the spinfits. Another tip to to getting a seal on the noble 4 is trying the Etymotic recommended way of inserting an IEM.sealing cycle but prior to the temperature of the seal reaching ambient. Refer to Test Methods F1921. 3.1.6 seal initiation temperature, n—on a heat seal curve, the sealing temperature/dwell pressure at which heat seal strength first begins to trend upward from zero heat seal strength. 3.1.7 sealing interface, n—the interface of the two web The easiest to do is hot water seal. Use distilled or demineralised water with a conductivity below 150 microsiemens and a pH of about 6 (5.5-6.5 is not uncommon). . The sealing test is also described by BS EN 12373-6. I don't know if it is exactly the same as the ASTM, I haven't carried out any gap analysis to find out.

It’s important to note that test rigs can accommodate single product testing and complete seal package testing. After all, sealing a hydraulic cylinder is a team effort, requiring all individual parts to interact as expected in unison. Sealing packages need to be carefully selected with the application and customer’s expectation in mind. What is good seal strength from a sealing process standpoint? Seal strength needs to be thought of in a multifaceted way. The process of determining what makes a good seal is the ‘Make’ pillar in ISO 11607. For the ‘Ship’ and ‘Store’ pillars you must think of what good enough seal strength is to maintain the integrity of the sterile .To test the integrity of mechanical seals fitted with a secondary containment seal. This document is general in nature and does not refer to site specific requirements. The site has the responsibility for ensuring that tests are carried out.

Twist ’N Seal® Pipe Sealing Plug Product Description and Features. Securely block off a variety of pipes from the inside with the Test-Tite Twist ‘N Seal Pipe Seal Kit. Quick and easy to use, this pipe seal kit allows you to install a temporary sealing plug inside DWV (drain, waste, and vent) pipe, stopping the water flow while you solder .Seam Sealing Tape is the perfect solution for waterproofing the vulnerable seam areas that can allow water to penetrate. But this seam sealing must still be tested to guarantee that the seam sealing tape is indeed carrying out its primary purpose and will make a Outdoor Jacket for example, fully waterproof.package inflation seal strength test. In the Creep Test, a whole package is inflated to a constant pressure, which is then held for a specified time, resulting in a pass/fail result (see Figure 5). Early users of the method for peelable seals used the test as an analogy for the pressure difference on the seals seen in the ETO To lay down the procedure for operating leak seal test apparatus. 2.0 SCOPE This SOP shall be applicable to Quality Control Dept. 3.0 RESPONSIBILITY . 5.4 The number of strips/blister taken should be sufficient to cover all the pockets of sealing roller. . Department 6.5 Hg: Mercury. Get ready to use editable documents in MS-Word Format .

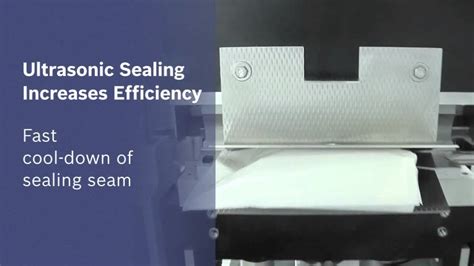

ultrasonic seal testing

Seals should be tested through proper testing methods and standards and then appropriate seals should be selected. This study reviews the dynamic seal test methods for high-pressure liquid .TE.com Store. Shop 60,000+ electrical parts and electronic components, available for purchase on TE.com . There has been good correlation between results obtained with the AD-3050 seal test and those obtained through water immersion testing. Features. Fast determination of sealing integrity; Multiple test fixtures; Easy load and release of .6. Seal test fixture capabilities Bench testing of rotary shaft seals Figure 2 shows the standard horizontal shaft test fixtures that are used to perform much of our instrumented rotary seal testing. These bench test fixtures are capable of testing seals up to 5” (127 mm) in diameter against various environments.Seal indicator for routine control of sealing seams for Tyvek ® /film packaging; Made of uncoated Tyvek ® /foil material (HDPE) according to DIN EN 868-9, printed with a gridded indicator field; Reliable inspection of the sealed seam due to optimal contrast . Order number: 200-321 HDPE-SEAL-TEST 100 pc

Sealing methods for leak testing Sealing technology is very important to reliably performing leak tests. Here, we list some topics related to actual sealing methods and sealing technology.1.Sealing gaskets. Gasket seals; O-ring seals; Recommended design for O-ring grooves; Sealing WORKs with large openings; 2. Clamp mechanisms. Tooling stoppers

The Sepha PakScan is a non-destructive test method. The machine performs a dry seal integrity test enabling manufactures to recover packs that have passed the leak test and return them to the production line. The system can identify gross holes, leaks and weak seals down to 10μm* in up to 10 packs simultaneously within 30 seconds.

Various criteria such as the force required and the chamfering of the sealed seam are evaluated. Alongside the seal check, the ink test and the seal seam strength test, the peel test is a common method for assessing the seal seam quality of a sealing device. Performing the peel test makes it possible to detect and rectify faulty seals in good time. The drill tail of a rock drill meets high-frequency fretting in both the rotational and axial axes. The pure water seal is prone to damage and failure owing to its difficult working features and the low viscosity of the water medium. Orthogonal testing is used to simulate and model the Y-shaped seal ring to enhance the performance of the water seal. The maximum .

3.1.9 hot tack, n—strength of a hot seal measured at a specified time interval after completion of the sealing cycle but prior to the temperature of the seal reaching ambient. 3.1.10 hot-tack curve, n—a plot of hot-tack strength versus sealing temperature (see Fig. 3). FIG. 1 Test Strip Failure Modes F 1921 – 98 (2004) 2 Feed oil to 1 -2 sealing chamber at the aft sealing and check for oil leakage from seal 1 and drain plug of 2 -3 chamber; Now shut the drain plug of 2 – 3 chamber and fill oil from the top plug. . as far as I know it is only method for repairing seals, is there any test or class approved examination for bonded seals. Thank you in advance .

Standard design features and benefits ProTest take the guessing out of tray-sealing and peeling; The ProTest is an automated lid-peeling device, designed to measure and report the resistance offered by the film as it separates from the tray during the moment of lid peeling.. With its easy set-up, the user can specify the strength of peel required for the specific product, process, .

A life test system was designed and manufactured in which different parameters can be tested in the sealing construction. The life test system consists of two hydraulic pressure intensifiers, and .

The seal test confirms that all 3 parameters of the heat sealer process, namely the temperature, pressure and time are functioning correctly to ensure the efficient and secure sealing of sterilisation pouches and reels. Authentication of seal integrity Documentary evidence for future internal and external auditsThe people below all want to find a department store to visit in their city. There are descriptions of eight department stores. Decide which department store would be the most suitable for the people below. 1 Jasmine would like to find a store where they can eat outside, and her dad wants somewhere known for its good-quality suits. They also .

trucut scuff mark remover

seal strength test

19 de jul. de 2023 · Baixe o app Panflix: https://www.panflix.com.br/Inscreva-se no nosso canal:http://www.youtube.com/panicojovempan Entre no nosso .

Seal Test / Sealing Test department Store|food seal strength testing